2277 Longyang Rd. Pudong, Shanghai, China info@mixingchina.com

Planetary Mixer

NFLG planetary mixer is used in Tianjin, China

- Model: JN1000,JN1500,JN2000,JN3000,JN4000,JN4500

- Discharge volume: 1000-4500L

- Equipment highlights: The vertical axis planetary mixing mainframe, with no dead space in the trajectory, makes for high mixing efficiency and high mixing uniformity.

Planetary Mixer

Introduction& Advantages

NFLG planetary mixer adopts vertical axis planetary countercurrent two-way mixing method, which has a more complex mixing trajectory. Using this technology can meet the quality characteristics, advanced new formula and non-traditional aggregate mixing requirements of different concrete. For dry hard, semi-dry hard, plastic concrete and concrete of various proportions, it can be fully mixed in the shortest time, which meets the requirements of different working conditions. Especially in the precast concrete component industry, it is more widely used, such as urban subway segments, concrete pipe piles, concrete bridges, concrete boxes, lightweight concrete walls, synthetic fiber impervious concrete, self-compacting concrete, mortar mixing, refractory materials, ceramic particulate materials, etc.

- The trajectory of the planetary mixer has no dead angle, high mixing efficiency and high homogeneity (high mixing uniformity).

- Fast mixing, labor saving, high energy conversion rate and high utilization rate, effectively reduce energy consumption.

Parameters

| Model | JN1000 | JN1500 | JN2000 | JN3000 | JN4000 | JN4500 |

|---|---|---|---|---|---|---|

| Discharge volume(L) | 1000 | 1500 | 2000 | 3000 | 4000 | 4500 |

| Feed volume(L) | 1500 | 2250 | 3000 | 4500 | 6000 | 6750 |

| Motor power(kW) | 45 | 55 | 75 | 110/132 | 160 | 200 |

| Mixing bracket(nos) | 2 | 4 | ||||

| Slewing speed(rpm) | 11 | |||||

| Mixing support speed(rpm) | 36 | 33 | ||||

| Maximum size of aggregate(mm) | 60 | |||||

| work cycle(S) | ≤80 | |||||

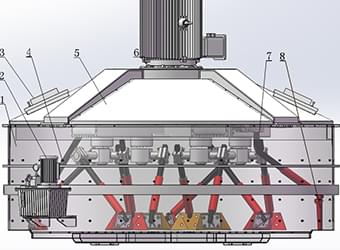

Host system

mixing evenly to meet high requirementsThe counter flow planetary two-way mixing with vertical axis design has compact structure, more complex mixing track, low noise, high torque, superior and stable performance, which can meet different concrete quality characteristics, advanced new mix formula and non-traditional aggregate mixing requirements, and solve the energy consumption, production capacity and efficiency problems of high-quality precast concrete plant.

Drive system

superior performance and high efficiencyThe integrated bidirectional rotating vertical planetary gear reducer mechanism has low noise, high torque, superior and reliable performance, high transmission efficiency, and flexible fluid coupling transmission protection.

Mixing system

durable and low maintenance costTwo sets of mixing arms with anti-wear protective sleeves in countercurrent and downstream, and the mixing blades are bi-directional hyperboloid design, which is fast and labor-saving. Using high-strength, high-hardness, wear-resistant and corrosion-resistant materials, long service life, less maintenance, low operation and maintenance costs.

Unloading system

stable and reliable quality controllableA manual pump is adopted to facilitate the control of the material volume of the prefabricated formwork, so that in the event of a temporary power outage or accident, the manual pump can discharge the concrete in the mixer at any time. Reliable sealing device can effectively ensure the mixing effect of sand and gravel. The small hydraulic pump station with stable operation drives the oil cylinder to open the material door, which can do multiple-point opening and hold to meet different discharge conditions.