2277 Longyang Rd. Pudong, Shanghai, China info@mixingchina.com

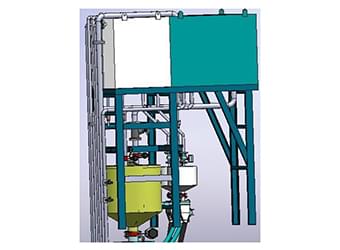

Hydraulic engineering concrete batch plant (With cold wind cooling system)

Hydraulic Engineering Concrete Batch Plant

- Model: HLSS360-2S6000L

- Productivity: 360-400m³/h

- Equipment highlights: Double spiral mixer, 20% energy saving as standard, maximum productivity up to 400m³/h

Hydraulic engineering concrete batch plant (With cold wind cooling system)

Introduction& Advantages

The HLSS360 hydraulic concrete batch plant developed by NFLG is the pre-cooled forced concrete batch plant with the largest production capacity of normal concrete and roller compacted concrete and the largest single plant capacity in the world so far. The productivity under standard conditions is 360-400 m³/h. Equipped with temperature control equipment such as aggregate silo cooler and flake ice device, it is mainly used for the construction of large-scale RCC hydraulic projects, which can meet the high-strength and large-capacity RCC pouring requirements of large-scale hydraulic and hydropower projects.The HZS series hydraulic concrete batch plant is divided into HZS150 and hzs200, the maximum theoretical productivity is 200m³/h, which can meet the concrete pouring requirements of small and medium-sized hydraulic and hydropower projects.

- Under standard conditions, the productivity can reach 360-400m³/h, and the production is efficient.

- Using high-quality materials and patented technology to reduce wear and tear and save costs.

Parameters

| Model | HLSS360-2S6000L | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Theoretical productivity (m³/h) | 360-400m³/h Normal concrete without ice | |||||||||||

| Mixer | JS7000 ×2 | |||||||||||

| Concrete discharge hopper | Double bucket double line, spacing 5m, clearance from the ground 5.1m | |||||||||||

| Control mode | Microcomputer automatic control, dynamic display and printing records | |||||||||||

| Material type | G1 | G2 | G3 | G4 | S1 | S2 | C | F | W | 1CE | A1 | A2 |

| Bin volume (m³) | 200 | 230 | 100 | 100×2 | 3 | 6 | 1 | 0.5 | ||||

| Weight value (kg) | 3500 | 4000 | 5000 | 4000 | 5500 | 1500 | 1000 | 750 | 300 | 60 | 30 | |

| Feeding capacity (t/h) | 1200 | 400 | 130 | 95 | 80 | 80 | 5.4 | 3 | ||||

| Aggregate particle blet conveyor | Coarse aggregate B=1000mm v=2.5m/sec, sand B=650mm v=2.0m/sec | |||||||||||

| Total power(kW) | About 1170kW ( excluding feed belt conveyor ) | |||||||||||

Batching system

smoothly discharge and no arch problemAdopt eccentric anti-arch door design with large inclination angle, vibrating lining structure and adjustable decompression plate to ensure the smooth discharge of materials. Hydraulics exclusive large aggregate batching and conveying system.

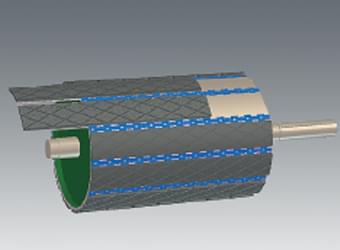

Conveying system

wear-resistant and durable, convenient maintenanceUsing replaceable friction disc type rubber roller, can be replaced within half an hour (Replacement of the old roller usually takes 4 days).Five cleanings + water cleaning to reduce belt abrasion.

Cement metering system

precise feeding and accurate meteringThe scientific design of the overall measurement system structure which avoid the main building and other factors that adversely affect the powder scale will not lead to accumulated materials, pull, dragging weighing scale to ensure the accuracy of measurement.

Liquid metering system

intelligent adjustment and controllable qualityCoarse and precise measurement of liquid admixture, equipped with adjustment devices such as liquid storage bag and manual ball valve, automatically realizes the function of overweight deduction, missing supplement function, timely adjustment, and improves the accuracy of measurement. With admixture leak-proof device to ensure the quality of concrete.

Dust removal system

efficient dust removal, energy saving and consumption reductionUsing pulse bag filter, the dust removal efficiency is as high as 99.9%, and low maintenance costs; The large fan actively extracts and removes dust, which can balance the pressure of each system in the main tower to ensure measurement accuracy and material discharge speed.

Demand customization

according to customer needs, scientific designBased on the actual needs of customer projects, NFLG provides scientific production solution design to help enterprises achieve profitability.